Simulation tools offered to NASA funded project researching ammonia in aviation.

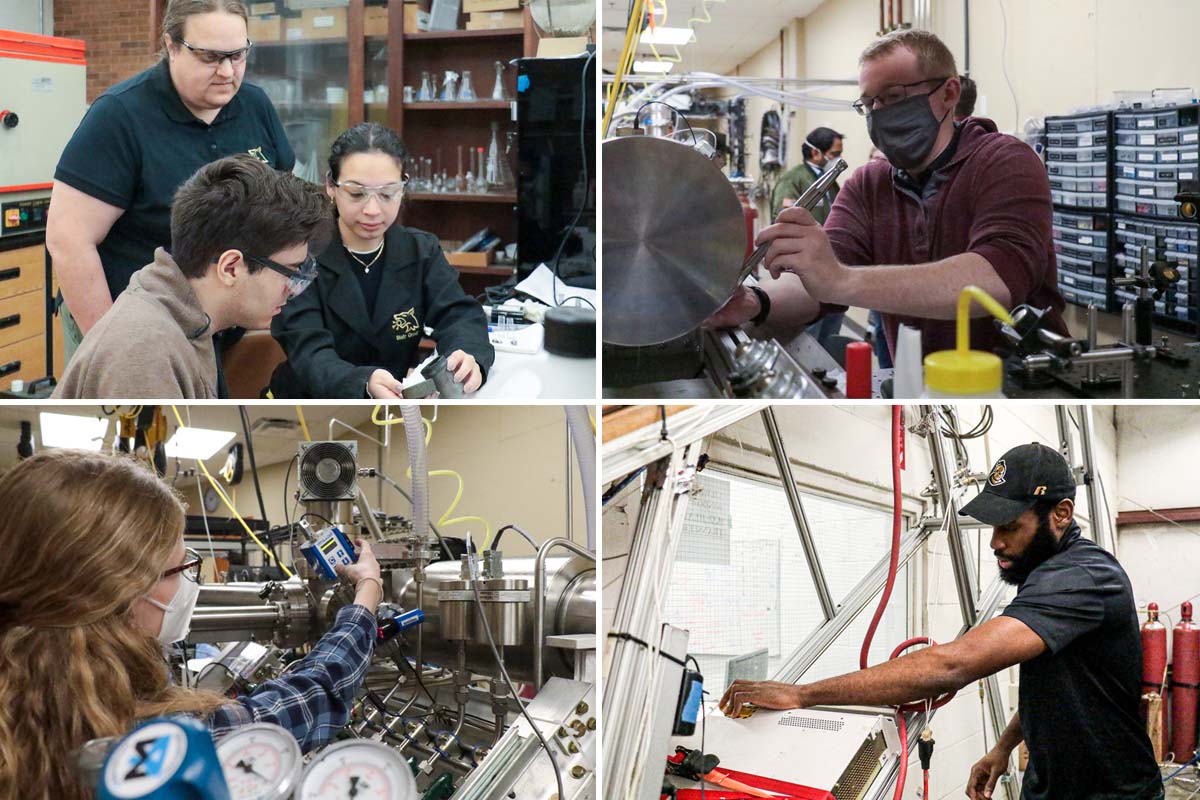

American company Ansys will support research led by the University of Central Florida and funded by a $10 million NASA University Leadership Initiative (ULI) five-year grant to accelerate aviation sustainability. The company revealed its simulation tools will be used in the five-year University of Central Florida study to analyze, test and qualify the use of ammonia as an alternative fuel to power zero-carbon jet engines.

The firm says the goal of the project is to use ammonia as a main hydrogen carrier by including chemical catalysis to leverage ammonia’s hydrogen component while only releasing ‘safe’ emissions.

Could the use of ammonia in aviation be the solution?

The feasibility of electric engines, hydrogen power, and sustainable aviation fuel have received the majority of the aviation industry’s search for fossil fuel substitutes.

Reaction Engines led a team that unveiled a design for a lightweight, modular cracking unit at COP26 last year. This gadget is perfect for use in aviation applications among other things because it uses heat from engine exhaust to partially split ammonia into a combination that resembles jet fuel. Inspired in part by NASA’s ammonia-fueled X-15 aircraft research program in the 1950s (which established unofficial records for flight speed & altitude), Reaction Engines created a design concept for ammonia-fueled jet engines in 2020. NASA’s vision for “climate-friendly” aircraft was introduced in June 2021, despite a break since the X-15. The organization prioritized electrification, efficiency enhancements, and alternative jet fuels like ammonia.

How the tech works?

Professor Jay Kapat of UCF Engineering, along with a few of his engineering colleagues from UCF and the Florida Space Institute, suggest using liquid ammonia (NH3) as aircraft fuel. This fuel will burn and produce environmentally friendly, safe emissions while supplying enough power to keep the aircraft in the air. Because ammonia is naturally soluble at high elevations, special handling is not required.

Ammonia is anticipated to be kept in fuel tanks on aircraft and at airports. Ammonia is frequently used as a fertilizer and, when combined with water, in certain cleaning products for the home.

The hydrogen transporter, ammonia, will undergo catalytic “cracking” to liberate hydrogen and nitrogen. To generate power, the hydrogen will be consumed in the engine’s onboard combustors. It is anticipated that airports and aircraft will keep NH3 in fuel tanks.

There will be a bonus when the hydrogen is released, according to Kapat. In addition to providing cooling, the conversion process can prevent engines from overheating and burning out. Improved engine efficiency and performance could be the result. This reduces the amount of power required from the primary engines by converting engine exhaust heat back into electricity for onboard use.

In addition, the group is creating new jet engine parts that will work with the novel fuel. Since the 737-8 class, according to Boeing, accounts for about 25% of all commercial aircraft, the team is utilizing it as a baseline.

Our work with ammonia

Our ammonia-related work Using ammonia, Universal Kraft offers a large-scale, environmentally friendly substitute for fossil fuels while maintaining the same functionality. These green power alternatives are fundamental for a sustainable and complete clean energy transition. Universal Kraft has been working on alternative and innovative energy carriers and storage solutions for a number of years. We established the business UH2 to maximize the decarbonization potential of renewable energy sources for the production of green hydrogen and ammonia.

Discover all our projects here and follow us on social media for more updates.